Complete juice beverage production line hot beverage bottling plant juice making packing machine

Characteristics of Fruit Juice Filling Machine

1. Using the wind sent access and move wheel in the bottle directly connected technology; canceled screw and conveyor chains, this enable the change the bottle-shaped become easier.

2. Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough..

3. The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution.

4. High-speed large gravity flow valve filling valve, filling fast, filling accurate and no liquid lose.

5. Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

6. Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Japan\'s Mitsubishi, France Schneider, OMRON.

Functions of Fruit Juice Filling Machine

Juice Rinser

-Rotative rinsing turret one treatment, fixed nozzles, with grippers.

-The grippers take the bottles from the inlet star-wheel while they are still driven by the star-wheel, thus guaranteeing a safe grip.

-After the gripping, the bottle is turned upside down and cantred above a spraying nozzle which directs a stream of rinse water into the bottle. After the draining period the bottle is turned over to an upright position again.

Juice Filler

-The star-wheels drive the bottles always "by the neck" through the rinsing, filling and capping steps. For the various types of bottle, it is easy to adjust the structure for the operator by our specialized design.

-Product bowl is to reduce the loss of heat.

-If the temperature is low than the setting value, the filling valves will stop and return the last beverage in filling valve to recycle tank and return to UHT again to sterilize with pump.

Juice Capper

-Rotative capping turret, suitable to the application of screw plastic caps on PET bottles

-The fixed part consists of the cap hopper, the cap feeder with relevant motor and the cam actuating the capping heads.

-The heads are raised and lowered by the action of a follower that is riding on a shaped cam.

Technical Data

| Model | CGFR8-8-3 | CGFR12-12-6 | CGFR18-18-6 | CGFR24-24-8 | CGFR32-32-8 | CGFR40-40-10 |

| Rinsing Head No | 8 | 12 | 18 | 24 | 32 | 40 |

| Filling Head No | 8 | 12 | 18 | 24 | 32 | 40 |

| Capping Head No | 3 | 6 | 6 | 8 | 8 | 12/10 |

| RatedCapacity (500ml) | 2000BPH | 4000BPH | 7000-8000BPH | 10000-12000BPH | 12000-15000BPH | 15000-18000BPH |

| Overall Size (mm) | 1900*1420*2000 | 2200*1600*2300 | 2450*1900*2300 | 2750*2180*2400 | 4000*2300*2300 | 4550*2650*2300 |

| Weight | 1.5T | 2.2T | 3.0T | 4.0T | 8.0T | 12.0T |

| Power(KW) | 3.0kw | 3.5kw | 4.0kw | 4.8kw | 7.6kw | 8.3Kw |

| Rated Voltage | 380V | 380V | 380V | 380V | 380V | 380V |

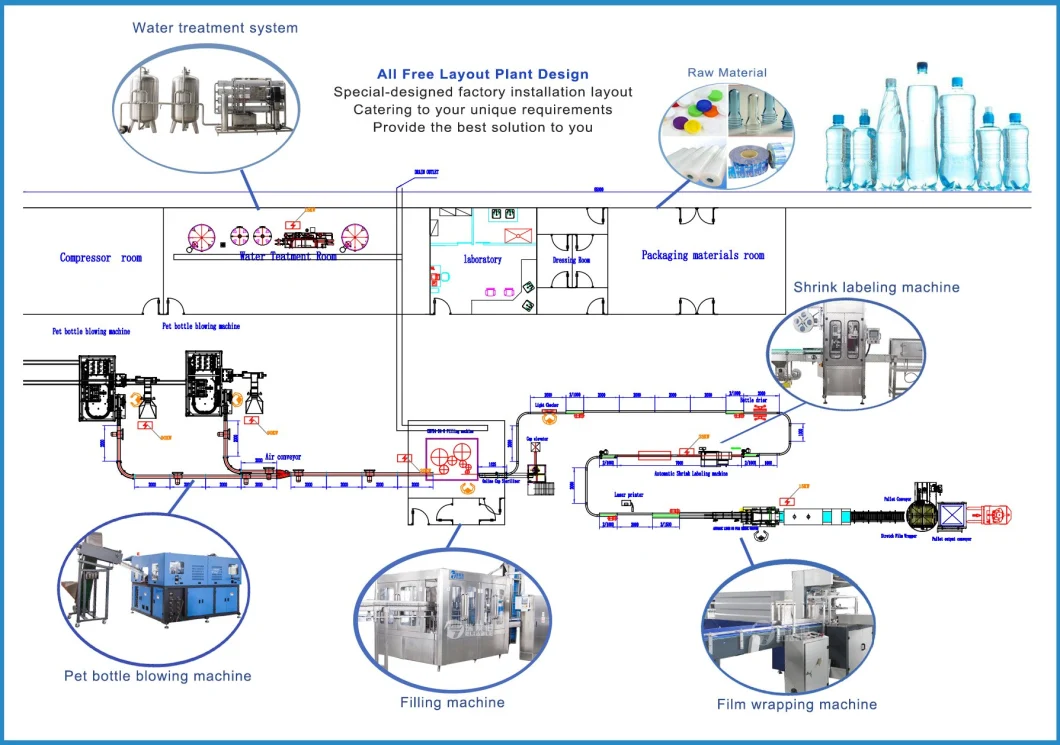

Complete Production Line

| Part 1. Water Treatment System | |||

| 1 | Water resource pump | 6T | 1 set |

| 2 | Sand filter | SYS-6 | 1 set |

| 3 | Active carbon filter | GHT-6 | 1 set |

| 4 | Precision filter | JML-6 | 1 set |

| 5 | High Pressure Pump | / | 1 set |

| 6 | Reverse Osmosis filter | RO-3 | 1 set |

| 7 | UV sterilizer | / | 1 set |

| 8 | Water Tank | 3T/H | 1 set |

| 9 | Pipe, Valves | SUS304 | 1set |

| Part2. Juice Mixing System | |||

| 1 | Syrup Melting Tank | 500L/H | 1 set |

| 2 | Beverage pump | 3000L/H | 4sets |

| 3 | Double heads filter | 2000L/H | 1set |

| 4 | Blending tank | 3000L/H | 2sets |

| 5 | Vacuum deaerator | 3000L/H | 1set |

| 6 | Homogenizer | 3000L/H | 1set |

| 7 | Heating and Cooling Crock | 2000L/H | 2sets |

| 8 | UHT Sterilizer(semi-automatic) | 3000L/H | 1set |

| 9 | CIP Cleaning system | / | 1set |

| 10 | Pipes and valves | / | 1set |

| 11 | Control Cabinet | / | 1 set |

| Part 3. Juice Bottle Filling & Packing System | |||

| 1 | 3 in 1 Juice Bottle Filling Machine | CGFR18-18-6 8000BPH | 1 set |

| Cap loader | / | 1set | |

| 2 | Light checker | DJ | 1 set |

| 3 | Bottle dryer | BD | 1 set |

| 4 | Full Automatic PVC sleeve labeling machine | SLM-150 | 1set |

| 5 | Date Printer | IC-55 | 1set |

| 6 | Automatic Shrink Wrapping Package Machine | RM-150A | 1set |

Reliable Service

Pre-sale service

1. Act a good adviser and assistant of clients enable them to get rich and returns on their investments.

2. Select correct and suitable equipment model

3. Design and make products according to clients' special requests

On-sale service

1. Reporting on machine situation from time to time.

2. Pre-check and accept products ahead of delivery

3. Drawing workshop layout

4. Train the first-line operators

After-sale service

1. Provide considerable services to minimize client's worries.

2. Assist clients to prepare for the first construction schedule.

3. Install and debug the equipment

4. Examine the equipment

5. Take initiative to eliminate the troubles rapidly

6. Provide perfect service

Company information

Our company has years of design experience and numbers of proprietary technologies. Reliable has been always committing himself to offer varies stand-alone devices and complete solution to drinks and brewers makers since establishment.No matter whether it is water filling, hot filling,Carbonated filling and aseptic cold filling, or in recent years the development of PET bottles and glass bottles of alcoholic filling line and oil filling line.Reliable is able to provide you all kinds of consummate projects and service!

Welcome to Zhangjiagang Reliable Machinery Co.,Ltd to see the Fruit Juice Filling Machine Running!