5000 Bottles Per Hour Carbonated Drinks Filling Packing Line

Descriptions of our carbonated beverage filling packing machines:

This machine is mainly used for carbonated beverage filling capping. The machine is 3 in 1 monoblock composed of washing, filling, capping, cap unscrambler in one unit. The rinser adopts overturning device, and filling system is gravity filling type, it's more stable and reliable. The capping head we adopt Italy technology.

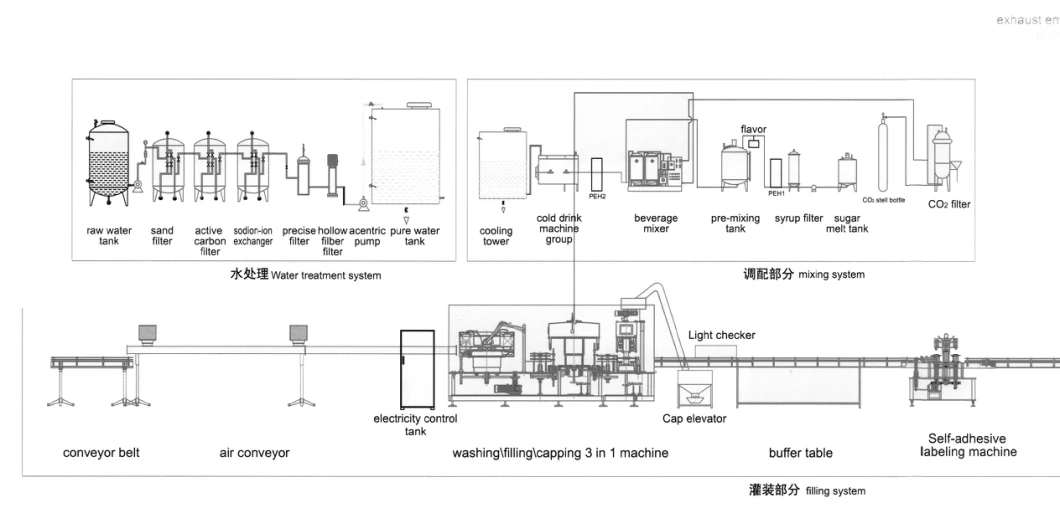

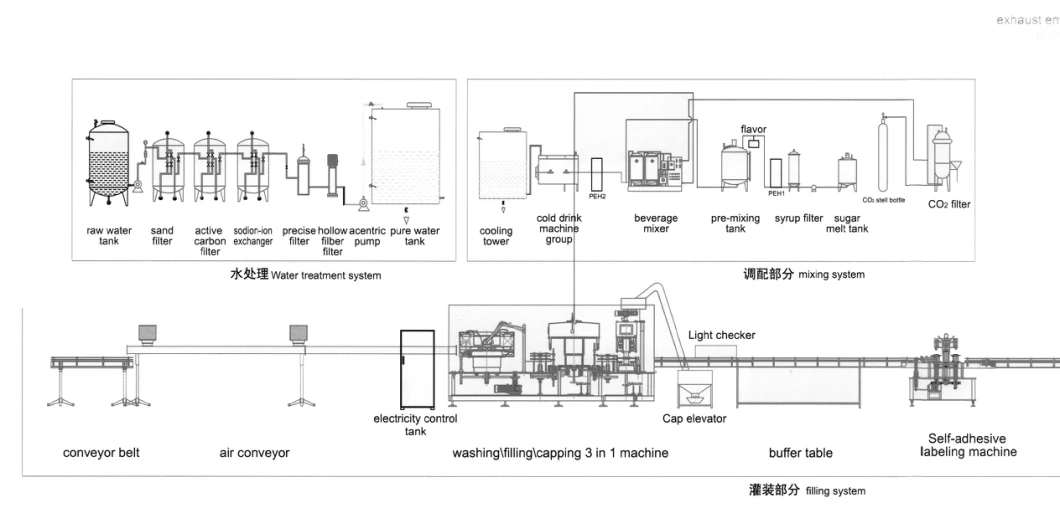

Technical Flows of Carbonated Drinks Filling Packing Machine:

| Model | DCGF16-12-6 | DCGF18-18-6 | DCGF24-24-8 | DCGF32-32-10 | DCGF40-40-12 | DCGF50-50-15 | DCGF60-60-15 | ||

| Rising heads | 16 | 18 | 24 | 32 | 40 | 50 | 60 | ||

| Filling heads | 12 | 18 | 24 | 32 | 40 | 50 | 60 | ||

| Capping heads | 6 | 6 | 8 | 10 | 12 | 15 | 15 | ||

| Capacity based on 500ml PET bottle | 3000BPH | 5000BPH | 7000BPH | 10000BPH | 15000BPH | 22000BPH | 24000BPH | ||

| Suitable bottle shape | PET bottles with different volume and shapes | ||||||||

| Suitable bottle diameter(mm) | Φ50-115 | ||||||||

| Suitable bottle height | 160-320mm | ||||||||

| Compressed air pressure | 0.3-0.7MPa | ||||||||

| Washing water pressure | >0.06MPa,≤0.2MPa | ||||||||

| Motor power (KW) | 2.2 | 3.5 | 4.5 | 6.0 | 7.5 | 9.5 | 11.2 | ||

| Dimensions(mm) | 2300*1600*2500 | 2600*1920*2550 | 3100*2200*2800 | 3850*3000*2850 | 4850*3800*2750 | 5750*3550*2750 | 6500*5500*2750 | ||

| Weight (KG) | 2800 | 3650 | 4800 | 6800 | 8650 | 10500 | 12800 | ||

Main Electrical components list:

| Item | Parts Name | Brand |

| 1 | PLC | SIEMENS |

| 2 | Inverter | |

| 3 | Touch Screen | |

| 4 | Switch | |

| 5 | Contactor | |

| 6 | Relay | |

| 7 | Solenoid Valve | AIRTAC |

| 8 | Water Pump | SOUTHERN |

| 9 | Sensor | AUTONICS |

| 10 | Air component | AIRTAC |

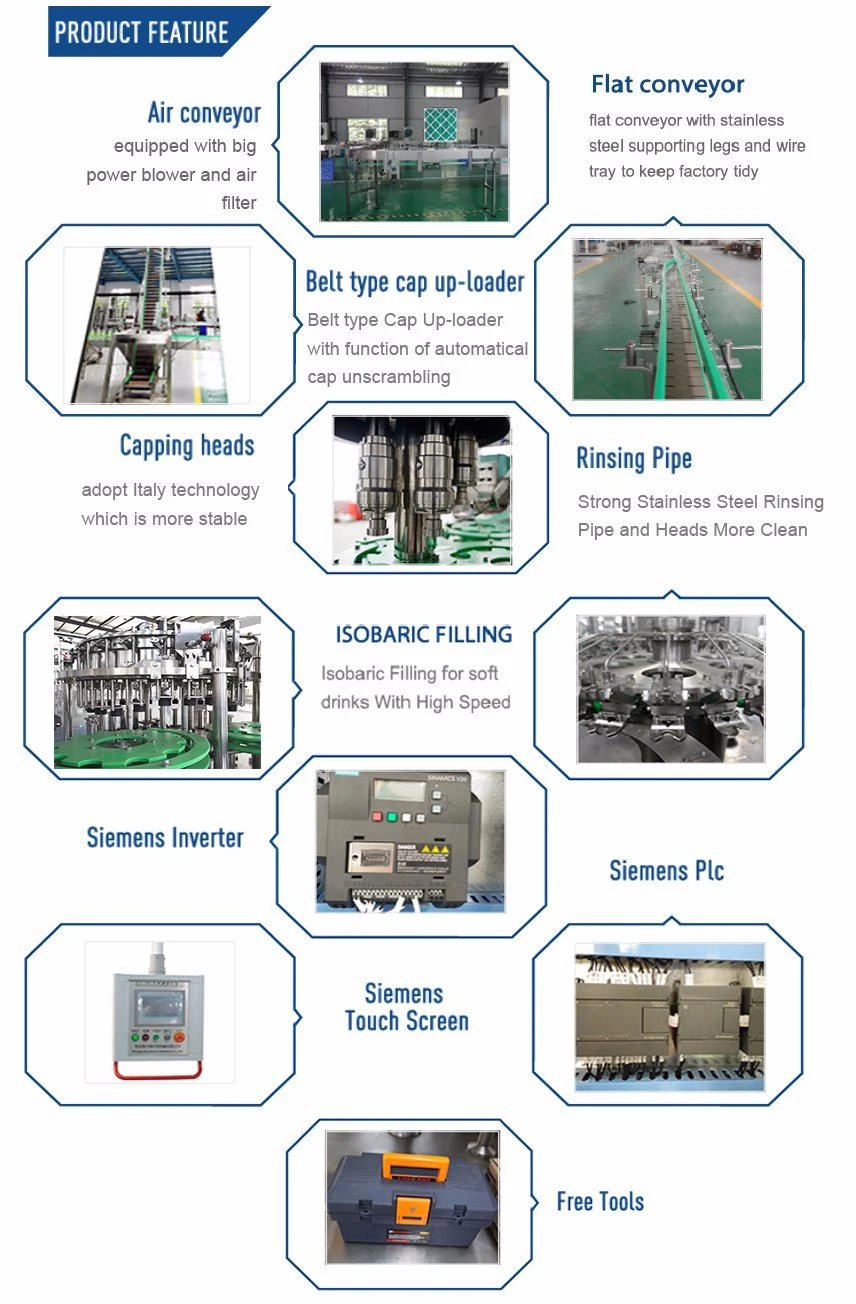

Features Of Carbonated Drinks Filling Machine:

- Air hanging type bottle conveying system makes changing spare parts more convenient.

- Famous SIEMENS brand PLC, and all the other electrical and pneumatic parts are world famous brand.

- Special designed stainless steel bottle gripper does not contact bottle neck thread parts, avoiding second contamination.

- Mass flow filling valve ensures high filling speed and exact filing level.

- Italy technology capping heads ensure high capping speed and capping precision.

Our Factory: